BRAM-COR Pure Steam Generators Mod. CPSG produce dry, saturated steam, suitable for sterilization of pharmaceutical production plants, for direct contact with Active Pharmaceutical Ingredients, for Parenteral and Non-Parenteral dosage form applications. The steam, when condensed, meets USP requirements for Water-for-Injection. The steam is purified using centrifugal and gravity separation methods.

cGMP, ASME and PED standards are baseline criteria in our Pure Steam Generators design and construction: material and instruments are certified and all welds are made by qualified welders.

In detail:

The system shall be fed with Purified Water and heated and heated using industrial steam, however heating can also be achieved using superheated water or with direct electrical power supply.

Capacities range: from 20 to 8000 kg/h.

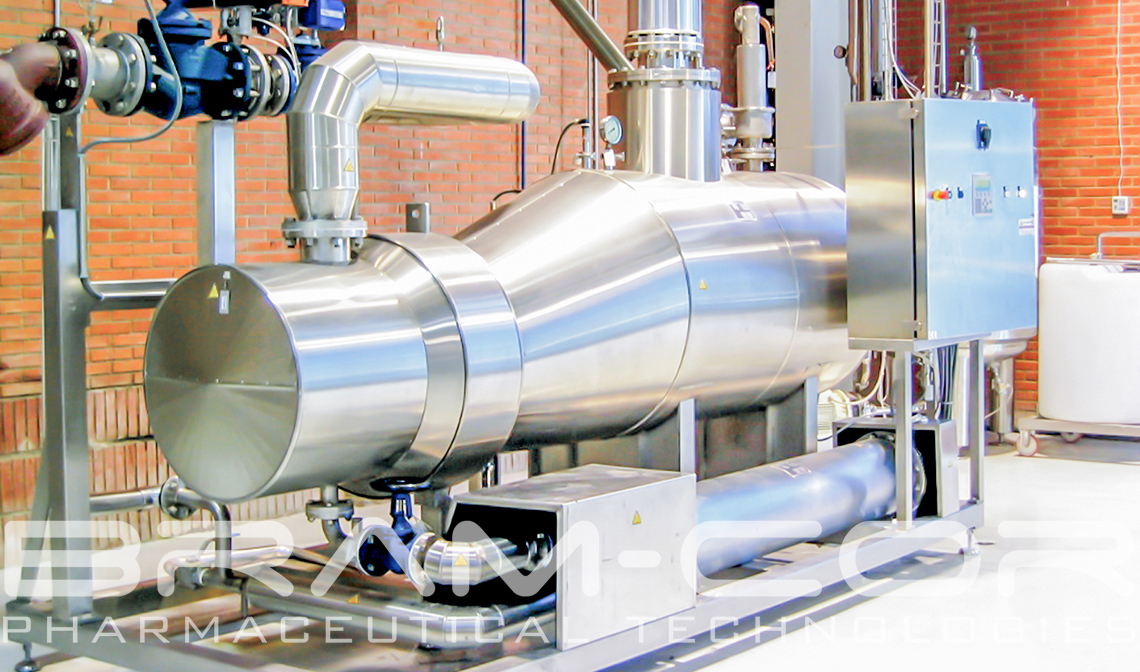

BRAM-COR KPSG Kettle Pure Steam Generators, provided with a horizontal evaporation chamber with kettle end, are also available for special space needs in case of high capacities.